INSPECTION EQUIPMENT

Professional Inspection Machine

- Able to confirm the material quality (preliminarily ensuring the material properties) including material appearance, width, flatness, bending, and burrs before cutting the masterbatch.

Size inspection for width and thickness

- Confirm the sample size after the slitting of the materials

- Use the micrometer to confirm whether the thickness of the material meets the customer’s shipment standards

- Use the vernier caliper to confirm whether the material width meets the customer’s shipment standards

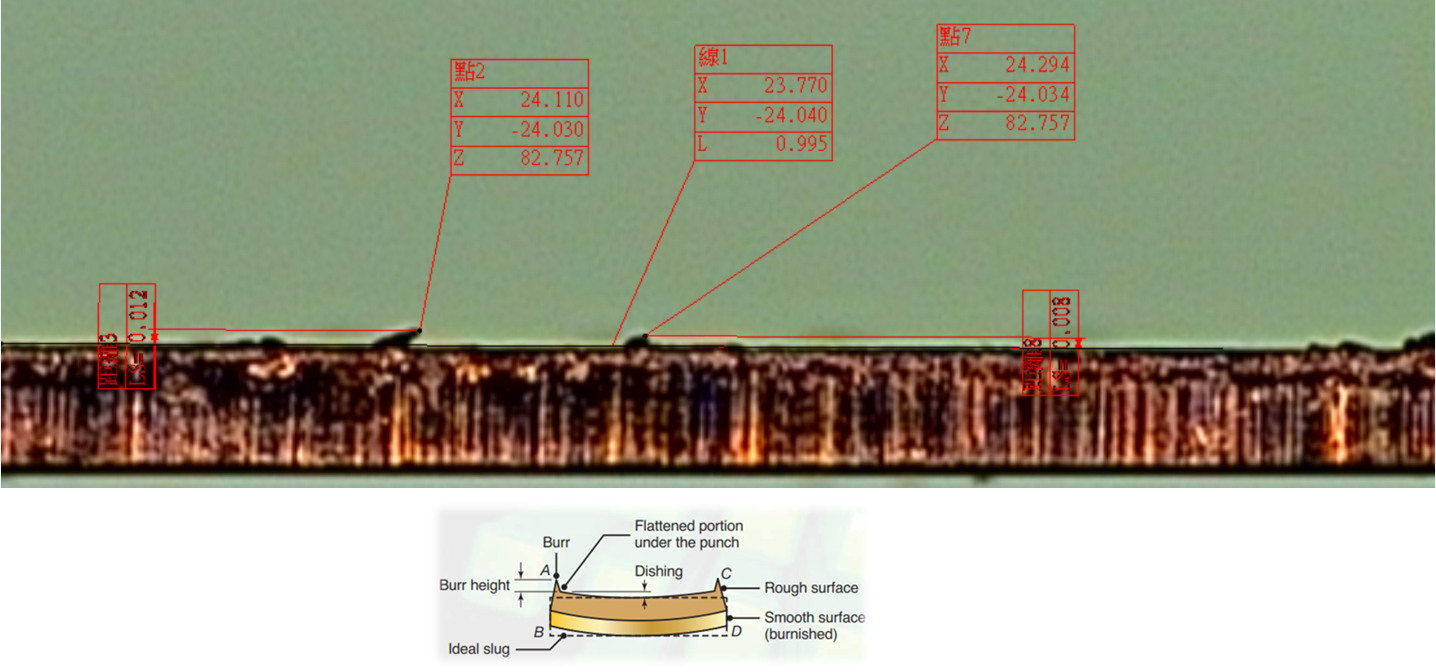

2.5D image measuring instrument

- Features:

1. Burr measurement

2. Product bending angle (inner R) measurement → Determine whether the mold design is appropriate

3. Size measurement

Burr inspection

- Causes of burrs → Poor mold clearance control, different ductility of materials, and different sharpness of molds

- Burr measurement: We use 2.5D image measurement instrument

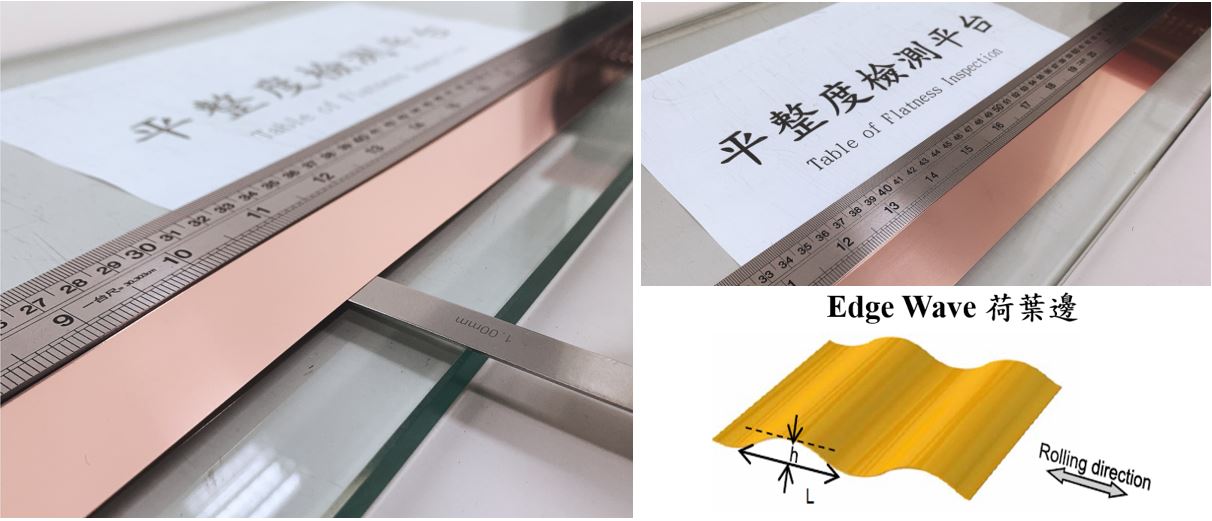

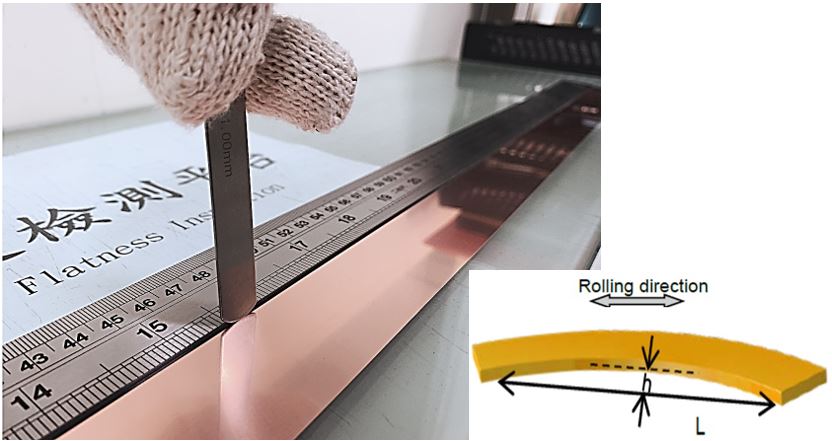

Flatness inspection

- Causes of poor flatness (cause of waves) → Improper control of the rolling process (causing uneven stress)

- Solution: Eliminate tension or stretch and straighten

- After cutting, the thickness gauge will measure the height of the distance between the platform and the materials

- International standard:Not exceeding 2mm/1 meter (i.e. distance between 1-meter sample and platform < 2mm)

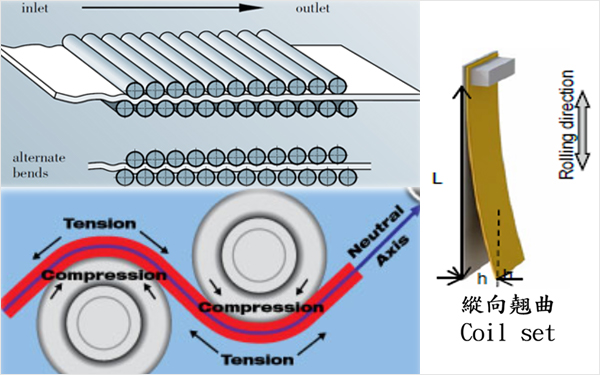

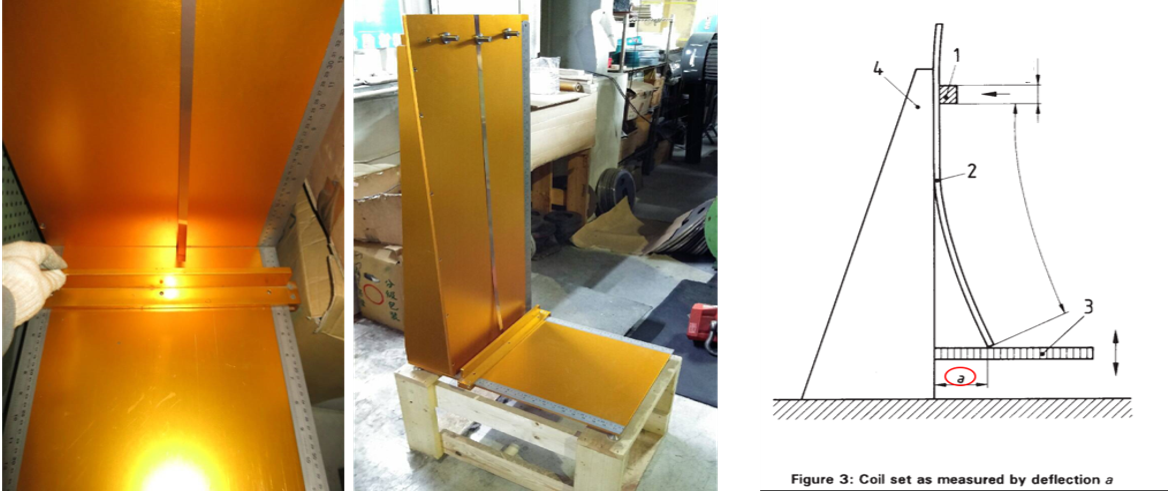

Warpage inspection

- Causes of warpage → Excessive residual stress when rolling the materials

- Solution: Low-temperature tempering or bending straighten

Warpage inspection platform

- nternational standards: Not exceeding 80mm/1 meter (i.e. the a of 1-meter sample < 80mm)

Curvature inspection

- Use a thickness gauge to measure the distance between the material and the iron ruler

- Causes of poor curvature → The material has wavy edges, and the thickness is uneven

- nternational standards: Not exceeding 3mm/1 meter (i.e. gap h of 1-meter long sample < 3mm)

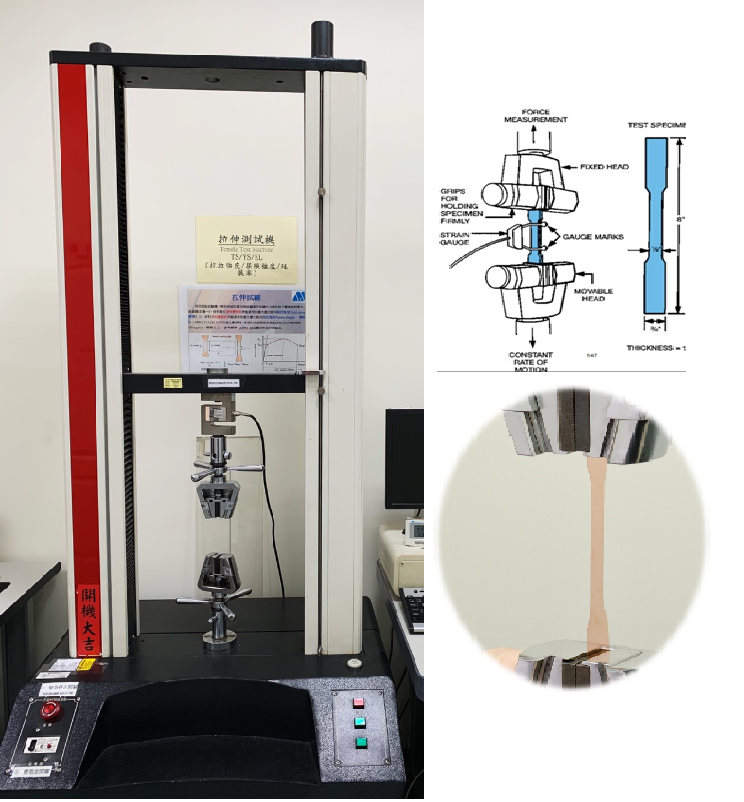

Versatile tensile testing machine

- The higher the tensile strength (TS) → the better the test results of durability (service life).

∵ Fatigue strength is directly proportional to tensile strength.

- The higher the yielding strength (YS) →The greater the normal force if the snap dome has a large downward pressing stroke and no yielding.

- The higher the elastic coefficient (E) → The greater the normal force if the snap dome’s downward stroke is small and not yielding.

- The higher the elongation (EL%) → The higher the height of draw extrusion.

- The major reasons for the difference from the results of the tensile test:

A. The material size conforms to the international standards or not

B. The existence of burrs on test sample

C. The test sample is clamped firmly or not

D. The fracture position of the test sample is within the standard range or not

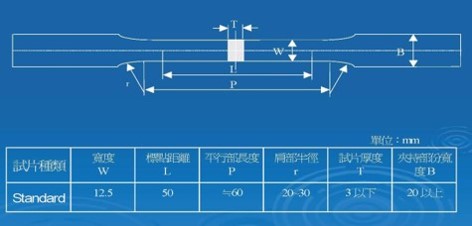

Versatile tensile testing machine – Test sample

- The size of the test sample is displayed in the figure

- The thickness is less than 3mm based on ASTM E8 metal material tensile test method

- Test 4 properties→Tensile strength (TS), yield strength (YS), elongation (EL), and elasticity coefficient (E)

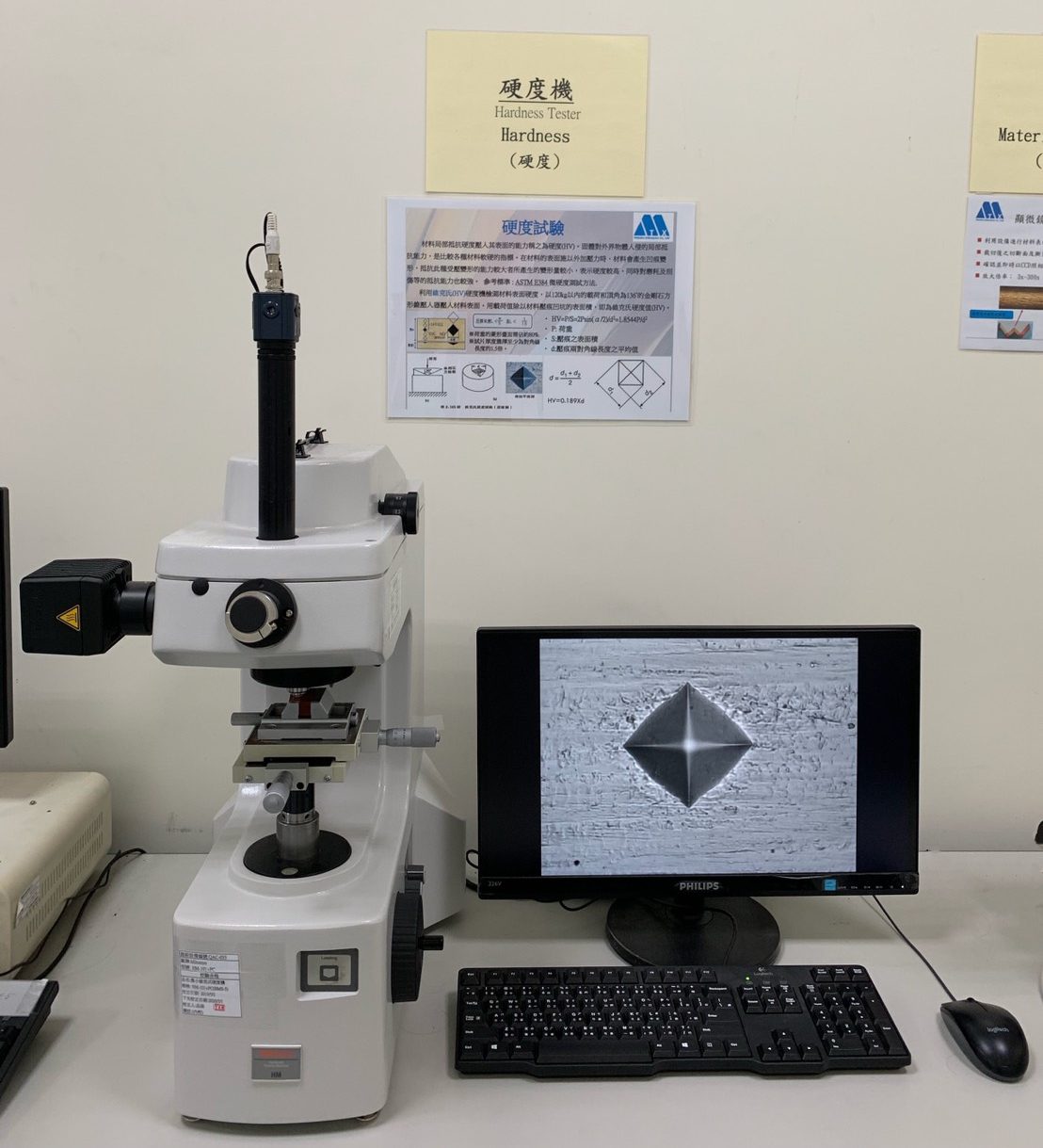

Hardness testing machine

- The major reasons for the difference in hardness tests:

A.Flatness of the test sample itself

B.Appropriateness of the pressing load

C.Symmetry of cross symmetry line

- Use the load test of 300g-500g for a test time of 10-15 seconds based on ASTM E3 microhardness (HV) test method

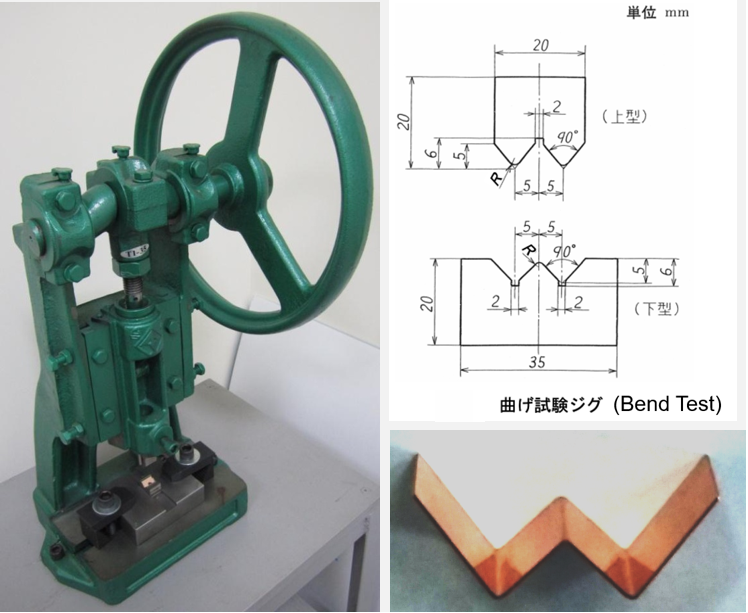

Manual stamping machine (90-degree bending test)

- Able to understand the damage resistance of materials during forming

- Place the sample in a W-shaped mold for W-shape (90 degrees), G/W and B/W bending tests

- We can test the inner radius R of the mold: The minimum R = 0.05mm, the maximum R = 1.5mm

- W-shaped bending stretches and deforms outward at the bended point. When being compared with the V-shaped bending test method, W-shaped bending is more stringent

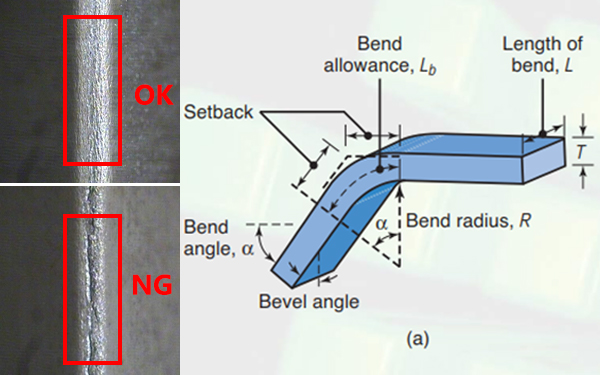

90-degree bending test

- R: Inner radius of the bended point

- T: material thickness (mm)

- Use the microscope to check whether there are cracks on the exterior side of the bended point

- The smaller the (R/T) value, the better the bending formability

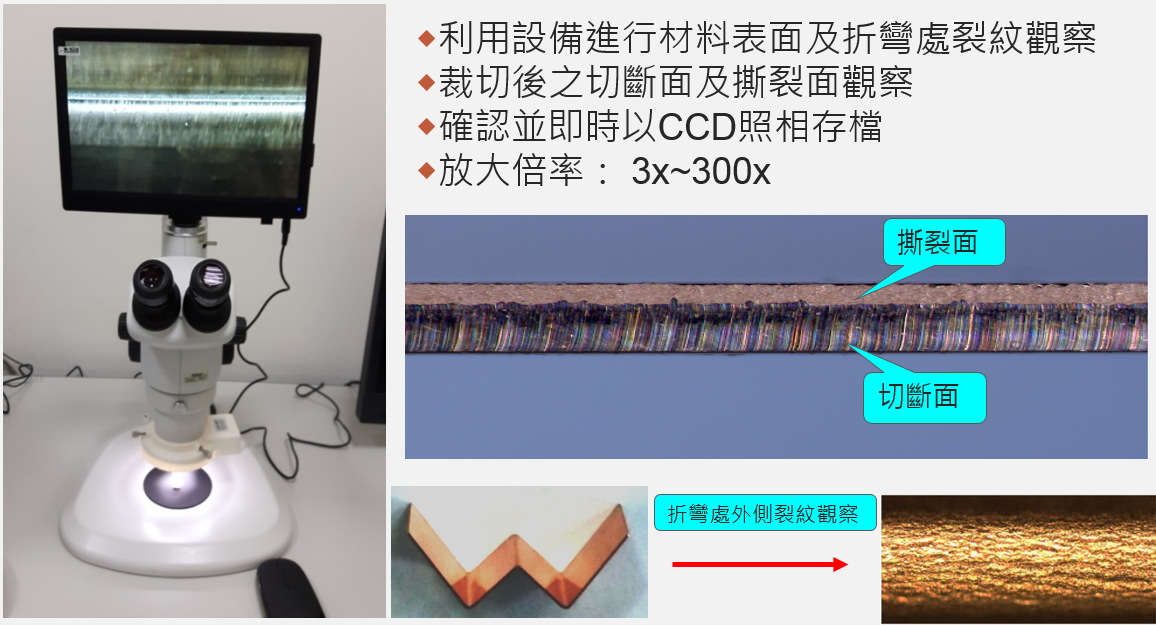

High-magnification microscopes

- Use equipment to observe cracks on material surface and bending

- Observe the cut and tear surfaces after cutting

- Confirm and record using CCD camera in a real-time manner

- Magnification: 3-300x

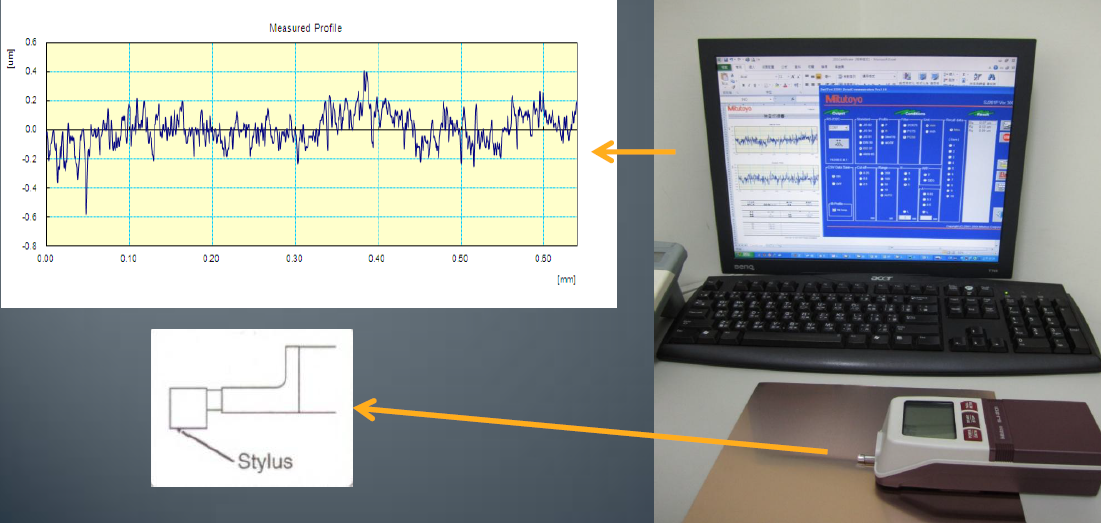

Surface roughness measurement instrument

- Smaller Ra → Longer service life of mold

→ Larger connector contact area, which could mitigate the temperature rise

- To mitigate temperature rise, increase electrical conductivity, thermal conductivity, and contact area

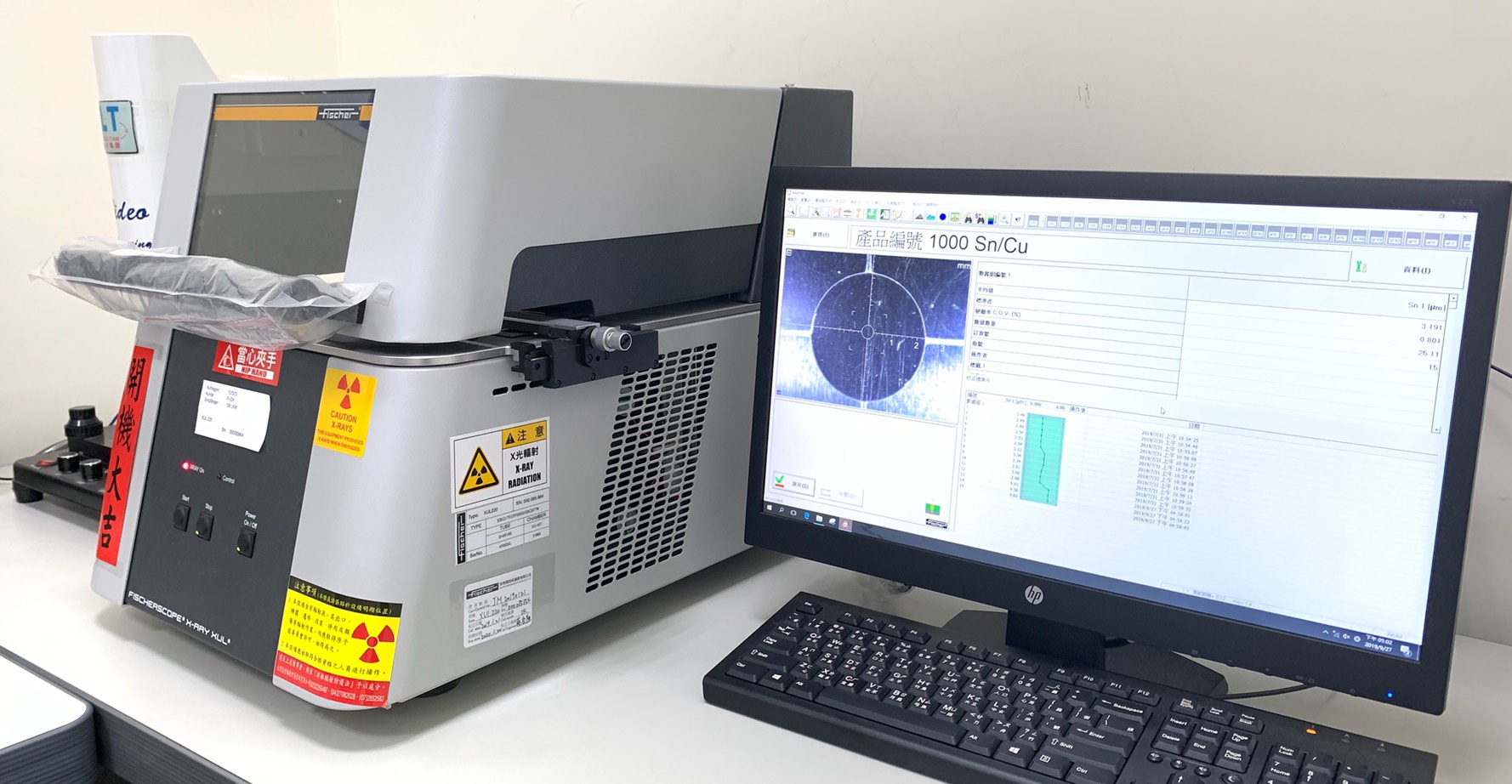

X-RAY electroplating film thickness composition analyzer

- We use X-ray fluorescent coating thickness measurement and material analyzer for non-destructive measurement of coating thickness and analysis of material composition.

- Simultaneous measurement for up to 24 kinds of elements ranging from chlorine (17) to uranium (92).

- Allowable tolerance range: ±5% for film thickness detection and ±5% for composition detection

Conductivity inspection machine

- Apply the principle of vortex testing to measure the conductivity of metal. The conductivity measurement unit is integrated as %IACS.

- High conductivity is able to mitigate temperature rise and contact resistance.

Fax:

(02)2999-9687

Tax:

27832528